Warp-Knit and Spunlace Fabrics for Automotive Seat Trim and Interior Components

Summary

Acme Mills partnered with a North American subsidiary of a leading Japanese automotive upholstery manufacturer to supply high-performance warp-knit polyester and spunlace fabrics for automotive seating and interior applications. The collaboration focused on delivering premium textile materials that meet rigorous industry standards for comfort, durability, and structural integrity. The project involved significant customization, precise quality control, and reliable delivery to align with the client’s manufacturing schedule.

This partnership demonstrates Acme Mills’ expertise in providing tailored material solutions that enhance the production process while supporting the client’s commitment to superior interior design and passenger comfort.

Project Specifications

Manufacturing Details

1. Material Preparation

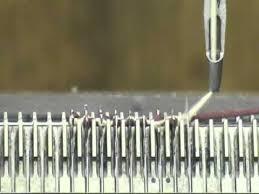

Warp-Knit Polyester: High-performance polyester yarns were prepared for use on advanced warp-knitting machines.

Spunlace Fabric: Hydroentangling technology was employed to create durable nonwoven fabrics from carefully selected fibers.

2. Fabric Production

Warp-Knit Process: Yarns were knitted using precision looms to produce flexible, stretchable fabrics optimized for durability and comfort.

Spunlace Process: Fibers were bonded using high-pressure water jets to create a lightweight yet strong material with excellent conformability for molding applications.

3. Customization

Fabric width and length were customized to the client’s specifications to minimize waste during the production process.

4. Roll Preparation

Rolls were slit to the required widths and re-rolled to ensure consistent tension and ease of transport.

5. Packaging and Delivery

Rolls were securely wrapped and moisture-protected for transportation.

Shipments were clearly labeled with detailed documentation to facilitate efficient inventory management.

Quality Control Steps

Incoming Material Inspection

In-Process Inspections

Final Inspection

Project Highlights

This project highlights Acme Mills’ ability to deliver high-performance textile solutions for automotive interiors. By providing customized warp-knit and spunlace fabrics engineered for durability, comfort, and structural integrity, Acme Mills supported the client’s production of premium seating and interior components. This collaboration reinforces Acme Mills’ role as a trusted supplier of innovative material solutions for demanding manufacturing applications.