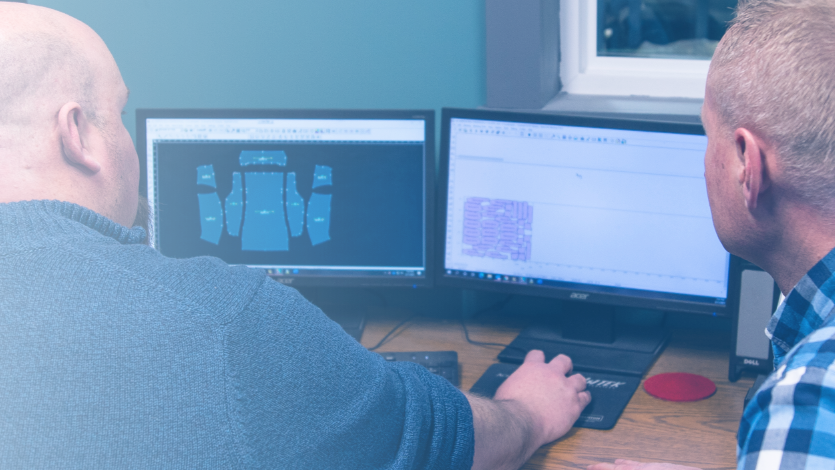

PRODUCT DEVELOPMENT

From Design to the Assembly Line, We’ve Got You Covered.

Your business can count on Fairway’s highly-skilled team to execute even the most complicated textile needs. Fairways process solutions are skillfully developed by our textile experts to maximize yields providing for better products produced faster.

When you come to us with a project in mind, we’ll collaborate with you to create a more manufacturable design that often optimizes your supply chain.

Reduce your soft goods manufacturing costs and time. Contact us for a FREE engineering consultation; click the button below to get started.

The Power of Fairway

Discover the driving force behind our innovative solutions. With decades of experience and a relentless pursuit of excellence, Fairway Products has become a trusted partner to industries worldwide. Our commitment to precision, quality, and customer satisfaction is the foundation upon which we build enduring relationships.

Applications

Development of disposable surgical gowns, drapes, and masks; creation of wound care dressings and filtration systems for medical equipment.

Design and production of transportation seating and interior components. From automotive to buses to airplanes and everything between.

Creation of industrial filtration systems for HVAC systems, dust collection, and liquid filtration; development of protective apparel for industrial workers.

Features

Benefits

Innovation

Our experts join forces to determine the best materials, layout, size, etc. to make the best product for your needs.

Design

Our engineers determine the most efficient way we can make your product while maintaining high-quality results.

Development

We have invested in highly effective and efficient technology to make products better, faster, and for an affordable price.

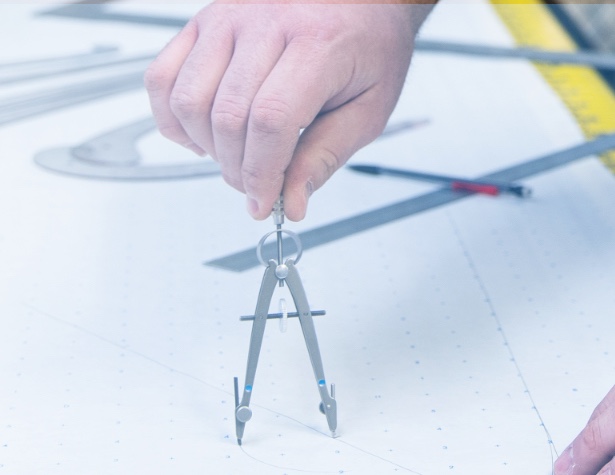

We Start with the Fundamentals

Our expert employees have the skills and the experience to take even the most basic napkin sketch of an idea and transform it into a product you’ll love.

When you come to us with a project, the first thing we’ll do is go through the vetting process. Then, our top experts determine the best raw materials for the product based on our extended experience to determine the most efficient process.

At Fairway, we’re committed to educating and empowering our employees so that the entire floor is involved in making the process and the products better, and doing so responsibly with an economy of materials and time, and a dedication to safety.

After we’ve engineered the manufacturing process for your product, we give it a thorough review and proceed to make a prototype. Because we’re committed to process efficiency, you get to enjoy a high-quality product for a price that you’re happy with.

Key Markets

Textiles

Manufacturing Plants

Summary: Fairway Products, a leader in innovative manufacturing solutions, recently completed a project to produce flexible ducting for industrial ventilation. Collaborating with a prominent global company in the industrial ventilation sector, Fairway Products delivered high-quality flexible ducting used with various blowers, fans, heaters, and ventilation equipment. This case study delves into the project’s specifications, uses, scalability, manufacturing process, and quality control measures, highlighting Fairway Products’ contribution to enhancing productivity and expanding production capabilities for their client.

Summary: Fairway Products, a leader in innovative manufacturing solutions, recently completed a project to produce flexible ducting for industrial ventilation. Collaborating with a prominent global company in the industrial ventilation sector, Fairway Products delivered high-quality flexible ducting used with various blowers, fans, heaters, and ventilation equipment. This case study delves into the project’s specifications, uses, scalability, manufacturing process, and quality control measures, highlighting Fairway Products’ contribution to enhancing productivity and expanding production capabilities for their client.

Project Specifications

Uses and Applications

The flexible ducting manufactured by Fairway Products is essential for temporary ventilation and air movement within industrial facilities. The ducting is compatible with a range of blowers, fans, heaters, and other ventilation equipment, making it versatile for multiple industrial applications such as:

- Construction sites

- Manufacturing plants

- Warehouses

- Temporary shelters

- Hazardous material handling

Scalability of the Project

The initial run of the flexible ducting project demonstrated Fairway Products’ ability to scale production efficiently. The collaboration began with a modest production batch to fine-tune specifications and ensure quality. Following the successful initial run, the project scaled up to meet the client’s global demands. Fairway Products’ advanced manufacturing capabilities allowed for seamless scalability, ensuring timely delivery and consistent quality.

Manufacturing Process

Material Inspection

The project began with the selection of heavy-duty vinyl material, chosen for its durability and flexibility.

Program Cutting

Using advanced program cutting techniques, Fairway Products optimized material utilization by nesting parts within the cut program. This process minimized waste and ensured precision.

Industrial Sewing

Skilled staff operated industrial sewing machines to assemble the cut vinyl parts into finished ducting products. This step was critical in maintaining the structural integrity and flexibility of the ducting.

Quality Control Steps

To ensure the highest quality of the flexible ducting, Fairway Products adhered to rigorous quality control measures throughout the manufacturing process:

Client Benefits

By collaborating with Fairway Products, the client gained significant productivity advantages. Fairway Products’ efficient production processes allowed the client to focus on other critical products within their facility. The expanded production capabilities provided by Fairway Products enabled the client to meet growing demands without compromising on quality.

Certifications

Fairway Products is proud to maintain ISO 9001:2015 certification, reflecting their commitment to quality management and continuous improvement.

Conclusion

Fairway Products’ expertise in program cutting and industrial sewing, combined with their dedication to quality, made them the ideal partner for this flexible ducting project. The successful collaboration not only enhanced the client’s productivity but also demonstrated Fairway Products’ capability to deliver high-quality industrial ventilation solutions on a global scale.