Unveiling the Science Behind Acme Mills’ Dymetrol® Suspension System: A Technical Perspective

When it comes to innovative seating solutions, Acme Mills’ Dymetrol® Suspension System stands out as a game-changer for engineers and manufacturers. Engineered to deliver superior performance in seating applications, Dymetrol® leverages advanced materials science to redefine comfort, durability, and efficiency. In this blog, we delve into the technology behind Dymetrol® and its technical specifications, offering insights into why it’s the go-to choice for modern seating systems.

The Science of Dymetrol®: Material Composition and Technology

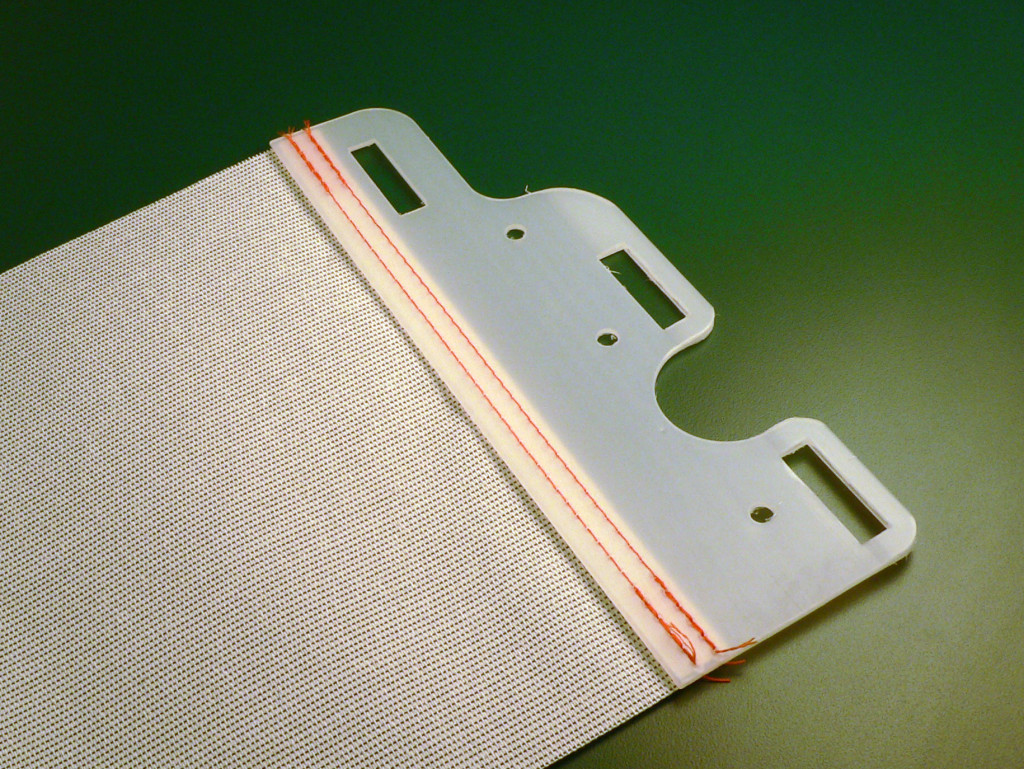

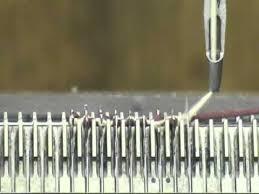

Dymetrol® is built on the foundation of high-performance, five-harness sateen weave fabric designed for use as a suspension material in seating systems. The key to its performance lies in its unique composition: a combination of spun polyester in the warp and specialized Hytrel® yarn in the fill. This blend creates a lightweight yet durable material capable of withstanding substantial tensile forces while maintaining flexibility and elasticity.

The system’s spring rate—a measure of how the material responds to load—is carefully calibrated for consistent performance. This allows Dymetrol® to distribute weight evenly, reducing pressure points and enhancing overall comfort. Moreover, its construction ensures durability under rigorous conditions, making it a reliable choice for automotive, aerospace, and other high-demand applications.

Technical Characteristics of Dymetrol®

- Construction and Dimensional Stability

- Weight and Strength

- Elasticity and Load Distribution

- Flammability and Safety

Dymetrol® is designed with precision weave patterns, including a warp density of approximately 100 ends per inch and a fill density in the range of 20–30 picks per inch. This ensures a balanced and stable fabric structure capable of maintaining integrity under varying environmental conditions. Its width can be customized to meet specific project requirements, providing versatility for a wide range of applications.

Engineered to be lightweight without compromising on strength, Dymetrol® boasts a fabric weight ranging between 9 and 11 ounces per square yard. This optimizes the balance between material efficiency and mechanical robustness. Its tensile strength, exceeding 200 pounds per inch in the warp and 80–100 pounds per inch in the fill, provides exceptional load-bearing capacity, essential for demanding seating environments.

With elongation properties that allow up to 16% stretch in the warp and up to 50% in the fill, Dymetrol® adapts to dynamic stresses, ensuring long-term performance without sagging. The material’s calibrated spring rate further enhances its ability to distribute loads evenly, reducing wear and tear while improving user comfort.

Safety is paramount in applications such as automotive and aviation. Dymetrol® meets rigorous flammability standards, including FMVSS-302 and FAR 25.853 for aviation use, ensuring compliance with industry regulations. These characteristics make it a preferred choice for engineers working on safety-critical projects.

Quality Assurance and Consistency

Acme Mills ensures that every roll of Dymetrol® meets strict quality standards. Suppliers implement Statistical Process Control (SPC) and other advanced quality management techniques to maintain consistency in material properties. No deviations from approved master samples are permitted without thorough evaluation, ensuring that every batch performs as expected in real-world applications.

Applications in Engineering and Design

Dymetrol®’s adaptability and performance make it a versatile choice for seating systems in automotive, aviation, and furniture industries. Its lightweight design supports fuel efficiency in vehicles and aircraft, while its comfort-enhancing properties elevate user experience in public transit and luxury seating.

For engineers, Dymetrol® represents more than just a material—it’s a solution that integrates seamlessly into cutting-edge designs, offering reliability and efficiency. Whether it’s reducing weight in electric vehicles or enhancing passenger comfort on long-haul flights, Dymetrol® meets the challenge.

Conclusion

Acme Mills’ Dymetrol® Suspension System exemplifies the intersection of science, technology, and innovation. With its advanced material composition, outstanding mechanical properties, and compliance with safety standards, Dymetrol® sets a benchmark for seating support materials. Engineers and designers looking for a high-performance solution that balances strength, flexibility, and durability will find Dymetrol® an invaluable addition to their toolkit.

For more technical insights or to explore how Dymetrol® can elevate your projects, contact us today.